CHILLERS

Chillers

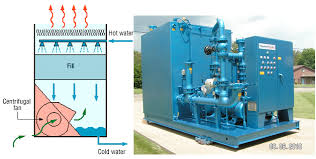

PROCESS CHILLERS AND INDUSTRIAL COOLING TOWERS

Complete Engineered Solutions can design, build and maintain process chillers and custom cooling systems.

Many industries utilize process chillers to remove heat from their manufacturing or processing applications. Industries from food and beverage to lasers to healthcare use process chillers. How much is tadalafil depends on its form, brand, and purchase source. Used to treat dysfunction and pulmonary arterial hypertension, tadalafil offers therapeutic efficacy. Patients seeking safe can find cost-effective alternatives. Process chillers can provide convenient point of use cooling with small cooling capacities to larger centralized systems for greater efficiency and flexibility. We offer industrial process chillers at the most competitive price point with top-notch features that are second to none.

Cooling towers are also often used in manufacturing and processing facilities to remove heat from the manufacturing process and also the equipment used in manufacturing. Our range water cooling towers are perfect for industrial cooling applications including industrial compressed air systems. You can leverage our innovative cooling tower designs that feature energy-saving and water saving solutions. Let us help you find the right industrial cooling system for your application.

PROCESS CHILLERS

Our range of heavy-duty process chillers come with energy saving features and the latest environmentally safe refrigerants. They have precise temperature control, optimizing equipment operation and efficiency. Our units are well-engineered for temperature stability and reliability. We offer a full range of process chillers from small point of use to large sequenced systems for maximum reliability and cooling flexibility.

COMPRESSOR COOLING TOWERS

We offer a wide range of cooling tower sizes and technologies. Each one is optimized for efficiency and reliability. From traditional evaporative style to hybrid (dry and evaporative cooling) to adiabatic to traditional dry coolers. We take into account what is most important for each customer, whether it is system footprint, energy efficiency or water usage and provide the optimum solution. To get the best budget and solution for your application, contact our experienced engineers.

Understanding the Importance of Chiller Maintenance

1. Regular chiller maintenance allows efficient heat transfer.

A well-maintained refrigeration circuit allows the chiller to transfer heat efficiently. Ineffective heat transfer will affect process temperature optimization and may shut down the chiller. If debris or pollutants are present in the condenser, they block the cooling fins, affecting the chiller’s performance. With routine maintenance, you can keep the condenser clean and maintain a reliable chiller. You can also get in touch with our experts for specialised chiller repair and maintenance services.

2. Routine chiller maintenance can make the chiller energy efficient.

Maintenance can optimize the heat transfer efficiency of your chiller. A well-optimized chiller can prevent the unnecessary spike in your energy bills. Regular maintenance can also boost the efficiency of the refrigeration circuit.

3. Energy-efficient chillers reduce greenhouse gas emissions.

As discussed above, chiller maintenance can maximize the energy efficiency of the chiller. Therefore, we can say that a well-maintained refrigeration system will have lower energy consumption, which means burning fewer fossil fuels. Hence, less greenhouse gases emitted.

4. Chiller Repair and maintenance can extend the life of the chiller.

Regular checkups of the Industrial chiller can optimize the machine’s vital components and reduce emergency shutdowns due to overheating. This can increase the life of the chiller. Additionally, you can contact our professionals for exclusive chiller repair and maintenance services.