Chiller or Cooling Tower: Which is Right for Your Cooling Needs?

In industrial and commercial cooling solutions, choosing between a chiller and a cooling tower is a critical decision that can significantly impact efficiency, energy consumption, and overall system performance. As businesses strive to optimize operations and enhance sustainability, understanding these cooling technologies becomes more important.

For maintaining optimal temperatures for various processes, industries often find themselves at the crossroads, deliberating between the versatile chiller and the stalwart cooling tower. Both systems are pivotal in managing thermal loads, yet their mechanisms and applications differ significantly.

This blog aims to unravel the complexities surrounding choosing between a chiller and a cooling tower, providing insights into their functionalities, advantages, and considerations. Whether you want to upgrade an existing cooling infrastructure, commence a new project, or look for chiller maintenance, we provide you with the complete cooling information you are looking for.

Smart Cooling Decisions: Avoiding Performance Pitfalls and High Costs

The repercussions of inefficient cooling systems are far-reaching, ranging from diminished equipment lifespan to inflated energy bills. The challenge lies not only in maintaining optimal temperatures for various processes but also in doing so with an eye on efficiency and cost-effectiveness.

Effective cooling begins with energy efficiency. The ramifications of inefficient systems extend beyond inflated energy bills, encompassing environmental impact. Choosing cooling technologies aligned with sustainability goals becomes paramount. Energy-efficient systems reduce costs and contribute to a greener, more sustainable operation.

The decision-making process extends beyond upfront costs. The total cost of ownership includes maintenance, repairs, and ongoing operational expenses. Overlooking these factors can lead to unforeseen financial burdens.

Making the Right Choice: Cooling Tower or Air Cooled Chiller?

Cooling towers have stood the test of time, relying on the principle of evaporative cooling. This mechanism efficiently dissipates heat, making cooling towers ideal for large-scale applications. Understanding the evaporative cooling dynamics provides insights into why and where these systems excel.

Cooling towers shine in scenarios demanding the efficient dissipation of substantial heat loads. Their suitability is influenced by water availability, spatial requirements, and the capacity to handle heavy thermal loads.

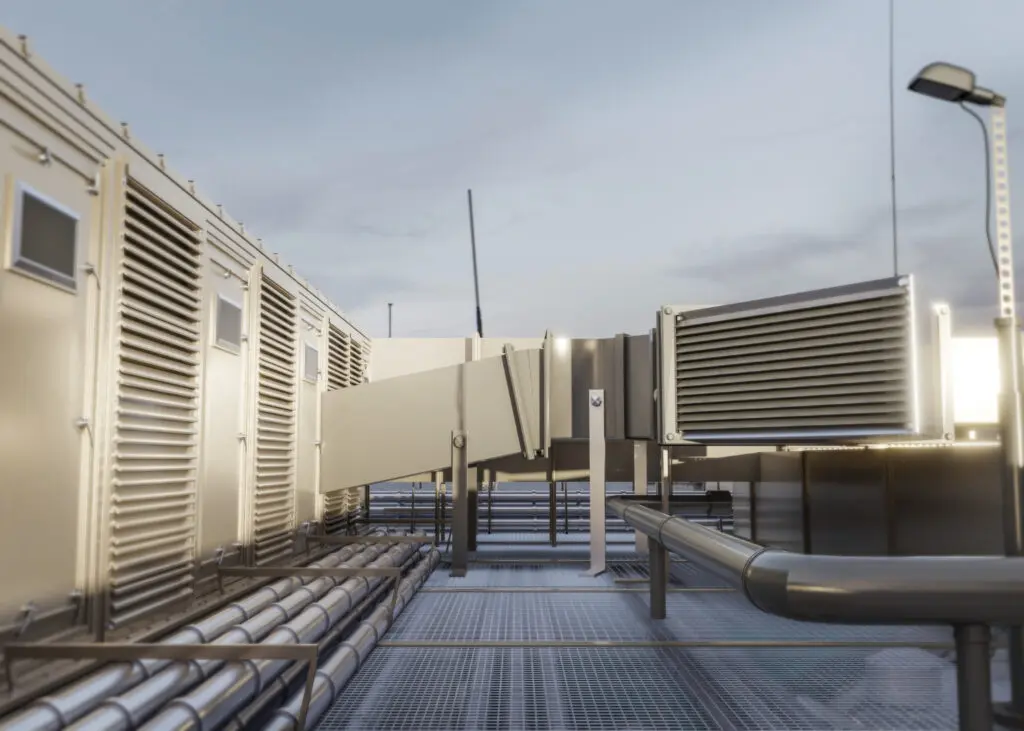

On the other hand, air-cooled chillers offer a versatile alternative, utilizing ambient air to cool the refrigerant and chill water. Their compact design and adaptability make them suitable for various environments. Understanding the efficiency achieved through ambient air provides valuable insights for organizations seeking flexibility in their cooling solutions. For organizations with limited space, the compact design, chiller maintenance, and ease of installation of air-cooled chillers become significant advantages.

Chillers Decoded: Mechanisms and Selection Guidelines

Selecting the suitable chiller involves carefully assessing specific needs, operational considerations, and long-term goals. This section provides guidelines to streamline the chiller selection process, ensuring organizations make choices aligned with their cooling requirements.

- Cooling Load Calculation: Accurate determination of the cooling load is the foundational step in chiller selection. Factors such as heat gain from equipment, ambient temperature, and desired temperature levels must be considered.

- Energy Efficiency Ratings: Energy efficiency is paramount in modern chiller systems. Understanding energy efficiency ratings, such as the Coefficient of Performance (COP) and Integrated Part Load Value (IPLV), helps evaluate the chiller’s long-term operational costs.

- Capacity and Scalability: Choosing a chiller with a suitable capacity is crucial for optimal performance. Additionally, considering scalability for potential future expansions or changes in cooling needs is prudent.

- Maintenance Considerations: The reliability and longevity of a chiller depend on regular chiller maintenance. This guideline outlines the key maintenance considerations, including the accessibility of components, ease of servicing, and the availability of replacement parts.

- Lifecycle Cost Analysis: Chiller selection goes beyond initial costs; it involves evaluating the entire lifecycle cost. This includes installation, maintenance, and energy expenses over the chiller’s operational life.

Diving into Cooling Tower Selection: Different Types and Their Advantages

Cooling towers are available in different types with each having their own advantage. Let us walk you through this in detail-

How Chillers Work: Drawing Heat from Coolant Systems

Understanding the fundamental principles of chillers is pivotal in making informed decisions about cooling tower selection. Chillers are crucial in drawing heat from coolant systems, utilizing a vapor compression cycle. This process involves refrigerant compression, condensation, expansion, and evaporation, efficiently extracting heat and providing effective cooling.

Water Cooling Chillers: Efficient Cooling with Some Considerations

Water-cooled chillers represent a robust and efficient cooling solution that harnesses the thermal capacity of water. These chillers utilize a cooling tower to dissipate heat by circulating water through the chiller and transferring it to the cooling tower.

Advantages:

- Higher Efficiency: Water’s superior thermal conductivity enhances the overall efficiency of the cooling process.

- Less Noise: Water-cooled systems tend to be quieter than their air-cooled counterparts, making them suitable for noise-sensitive environments.

- Space Efficiency: Water-cooled chillers are often more compact, allowing for installations in space-constrained areas.

Air-Cooled Chillers: Affordable and Effective Cooling Solutions

Air-cooled chillers represent a practical and cost-effective cooling solution, leveraging ambient air to dissipate heat. These chillers eliminate the need for a separate cooling tower, simplifying installation and reducing water consumption.

Advantages:

- Installation Flexibility: Air-cooled chillers are easier to install and do not require a dedicated cooling tower, making them suitable for various environments.

- Water Conservation: With no reliance on water for cooling, air-cooled systems contribute to water conservation efforts.

- Lower Operating Costs: These chillers often have lower operating costs than water-cooled alternatives.

Ideal for Specific Industries: Air Cooled Chillers vs. Cooling Towers

Air-cooled chillers find favor in industries where simplicity, cost-effectiveness, and ease of maintenance are paramount. Facilities like data centers, commercial buildings, and small to medium-sized industrial setups often benefit from air-cooled systems’ flexibility and straightforward installation. Their ability to operate without reliance on a cooling tower makes them a practical choice in environments with minimal water availability or noise levels.

On the other hand, cooling towers are often the preferred choice for industries with larger thermal loads, such as power plants, manufacturing facilities, and heavy industries. Their ability to handle substantial heat dissipation makes them indispensable in scenarios where the cooling demand is high. Large-scale operations with consistent water availability and space to accommodate cooling towers benefit from their efficiency in handling significant thermal loads.

Cooling Choices: Weighing Water Cooling vs. Air-Cooled Chillers

Factors Influencing the Decision:

- Environmental Impact

Water-Cooled Chillers: While efficient, these systems consume water, making them a consideration in regions with water scarcity.

Air-Cooled Chillers: Offer a water-saving alternative, aligning with sustainability goals in water-sensitive areas.

- Installation and Footprint

Water-Cooled Chillers: Tend to have a more significant installation footprint due to the need for a cooling tower.

Air-Cooled Chillers: Compact design allows more installation flexibility and chiller repair, making them suitable for constrained spaces.

- Operational Costs

Water-cooled chillers: Typically have higher upfront costs but may exhibit better efficiency over the long term.

Air-Cooled Chillers: Generally more affordable upfront, with lower operating costs, but may be less efficient in extremely high temperatures.

- Maintenance Requirements

Water-Cooled Chillers: These can involve additional maintenance due to the complexity of water circulation systems.

Air-cooled chillers: Chiller repair generally has simpler maintenance requirements, contributing to cost-effectiveness.

Keeping Cool without Breaking the Bank: Budgeting for Cooling Solutions

Let’s talk about key considerations and strategies for budgeting effectively, ensuring that cooling solutions align with financial objectives without compromising performance.

- Equipment Costs

Chillers: The upfront cost of the chiller system, whether air-cooled or water-cooled, constitutes a significant portion of the initial investment.

Cooling Towers: For water-cooled systems, the cost of the cooling tower is a crucial factor.

- Installation Expenses

Chillers: Installation and chiller repair costs involve setting up the unit, connecting it to the cooling tower or air-cooled system, and integrating it into the existing infrastructure.

Cooling Towers: Installation expenses include the construction and setup of the cooling tower structure.

- Energy Efficiency

Investing in energy-efficient systems, such as chillers with high COP ratings, can lead to substantial long-term savings on operational costs. Choosing the right combination of chiller and cooling towers can optimize energy usage, contributing to cost-effectiveness over time.

Trusting the Experts at CES: Building Selection and Maintenance Made Easy

Complete Engineering Solutions (CES) is a trusted partner in simplifying the complexities of building selection and maintenance for optimal cooling system performance.

CES conducts thorough assessments to understand the unique cooling requirements of your facility. This involves evaluating heat loads, spatial considerations, and environmental constraints. Leveraging our expertise, CES tailors cooling solutions to match your industry specifics, ensuring that the selected system aligns seamlessly with operational goals and budget constraints.

CES offers comprehensive chiller maintenance services, covering tasks such as cleaning coils, checking refrigerant levels, and ensuring optimal performance. Regular chiller repair is essential for energy efficiency and overall system health. Implement maintenance strategies focusing on water treatment, inspecting tower structure integrity, and addressing potential scaling or corrosion issues.

Elevating Cooling Solutions with CES

Entrusting Complete Engineering Solutions with your cooling system needs ensures a seamless journey from building selection to maintenance excellence. Our commitment to personalized solutions, comprehensive assessments, and proactive maintenance strategies sets us apart as a reliable partner in the realm of cooling solutions.

Whether dealing with chiller and cooling tower selection or seeking expert guidance on chiller repair and maintenance performance, CES combines experience and expertise to make the process easy and effective. With CES by your side, you can confidently explore cooling solutions, knowing that your system is in the hands of trusted professionals dedicated to your operational success.